We have been pursuing the technology to polish metal surfaces mechanically through longtime research.

Flow Path Inner Surface Polishing (Flow Polishing)

In this method, fine abrasive is added to a medium and flows on by high pressure for polishing.

Features

- Inner uneven surfaces can be flattened

- Specialized washing with pure water enables clean inner surface finish

Applications

- Flow-polishing the inner surface of stainless narrow tube enhances the smoothness of the flow path.

Before polishing

After polishing

- Polishing the water conduit of a heat exchanger stabilizes the fluid flow.

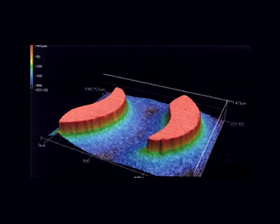

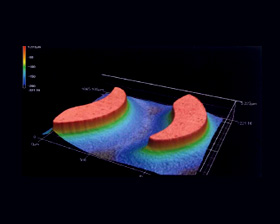

Example (Laser Analysis)

Before processing

After polishing

|

Ra |

| Before polishing |

0.506 |

| After polishing |

0.395 |

Tool Mark Removal Polishing (Jitterbug Polishing)

Tool marks created as a result of machining can be removed.

Features

- Shallow scratches can be eliminated

- Surfaces can be finished at a preferred surface roughness ranging from a mirror finish to a satin finish.

Application Example

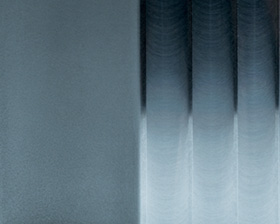

After machining

(Tool marks created as a result of machining are noticeable)

After Jitterbug polishing

(Surface finish patterns with no regularity)

- Surface finish of semiconductor and FPD (liquid crystal and organic EL) manufacturing equipment components

3D Polishing (PSP and VSP processing)

In this method, a workpiece is flown or vibrated in the abrasive to polish it without causing deformation.

The defects on the processed surface layer are eliminated to enhance the natural durability of the material.

Features

- Tiny burrs generated on end faces as a result of pressing or machining can be eliminated without changing the product dimensions.

- Since this is a mechanical defect elimination method, no corrosion due to chemical residue is caused.

- The end faces of a thin plate are formed, resulting in the ensuring of fatigue strength

- Contaminations brought into the uneven surface on an end face (processed surface layer) can be eliminated

- Plate surfaces can be flattened (The roughness of rolled surface can be improved)

Improvement Example

An example of an improvement of surface roughness (Stainless steel)

|

Surface roughness Rmax(μm) |

| Material |

Before PSP process |

After PSP process |

| Stainless steel |

0.3~0.5 |

0.2~0.3 |

| Aluminum alloy |

1.0~3.0 |

0.9~1.0 |

Applications

- Hard disk internal components

- Processing of end faces of etched parts

- Polishing of external surfaces of narrow tubes