We can vacuum-braze heat-resistant alloys, stainless steels, iron-based alloys, aluminum alloys, and copper alloys to achieve the airtightness at the Helium leakage level.

About Vacuum Brazing

This technology is used to join metals together by applying filler metal (such as Ni and Ag filler metals) to the stainless steel, nickel, or copper base material and heating them in a vacuum. It is also possible to braze aluminum material (using aluminum filler metal).

Features of Vacuum Brazing

- It joins metals with complicated shapes and joins at multiple points simultaneously.

- Heating the entire metals realizes joining with low distortion and high precision.

- Joining metals in a vacuum prevents oxidized film from being formed and provides a good finish.

- The effect of degassing in a vacuum prevents air bubbles from remaining at the joining area.

- Using no flux enables no contamination and bright treatment.

Features of Our Products

- We can join heat-resistant alloys, stainless steels, iron-based alloys, aluminum alloys, and copper alloys.

- We can design and fabricate three-dimensional steric flow path structures that prevent multiple fluids from being mixed and structures with a flow path that can heat or cool without any dead space.

- This technology can be coordinated with polishing, machining, and surface treatment technologies.

Examples of Vacuum-Brazed Products

laminating-brazing thin plates.

We are good at brazing thin-walled pipes with a thickness of 50 μm and laminating-brazing thin plates. For example, we can fabricate not only sensor pipes for MFCs (Mass Flow Controller), pneumatic equipment components, and electrostatic chuck base materials but also complicated flow path components, such as heat exchangers, transfer fixtures, and multi showerheads.

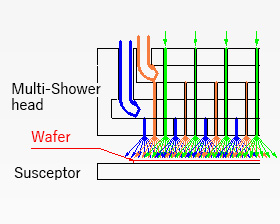

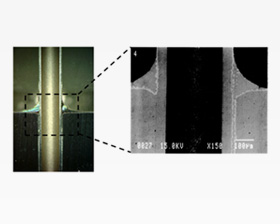

Cross section of the joining area of a shower plate for MOCVD equipment Number of pores: 5,200, pore diameter: φ 0.6 mm

Film formation by shower plate for MOCVD equipment

Joining of a thin-walled pipe Pipe diameter (external diameter): φ 0.4 mm, inner diameter:φ 0.3 mm

Large vacuum furnace 800 (Width) x 1,300 (Depth) x 800 (Height) mm

Gold and Silver Brazing

We can also perform joining using gold and silver filler metals, which are used in joining different kinds of metals such as copper and stainless steel, copper and copper, and copper and ceramic. Vacuum furnaces and high-frequency induction furnaces can be used in house to perform heating and brazing.