September 1951

Established Japan Industrial Materials Co., Limited at Nihonbashi Muromachi, Chuo-ku, Tokyo.

1951 -

- Established the company for selling nonferrous metals.

- Started sales of nickel, cobalt, and metal powders.

Commentary

Nonferrous metals

Nonferrous metals

- Started sales of specialty electrodes and welding materials to move into the LNG, desalination plant, and nuclear power fields.

Commentary

As the heat-resistant structural materials for the low-temperature environment in large-sized LNG (liquefied natural gas) storage tank and reactor containment vessels, the demand for nickel-based welding materials increased.

July 1963

Established the Saitama plant in Hanyu City, Saitama Prefecture.

Commentary

We established a manufacturing base in order to respond requests from our customers to which we were supplying nickel alloy magnetic materials to supply pressed and heat-treated products.

Former building of the Saitama plant

Former building of the Saitama plant

1960 -

- Started sales of soft-magnetic materials (K-M series electromagnetic stainless steels).

K-M series

Commentary

As corrosion-proof stainless steels with soft-magnetic properties, the handling of materials that are widely used for solenoid valves and pumps was started.

Electromagnetic stainless steels (K-M series)

Electromagnetic stainless steels (K-M series)

- Started sales of components made by magnetic-annealing or pressing soft-magnetic materials (permalloys) for the audio field.

Commentary

Our rare metal magnets which are attached to the cantilever for the cartridge (magnetic head) for LP records captured approximately 90% global market share mainly in the European and American markets as the beginning of our internationalization.

Audio magnetic head, phonograph needle cartridge, and VTR sound head

Audio magnetic head, phonograph needle cartridge, and VTR sound head

-

- Cartridge (magnetic head)

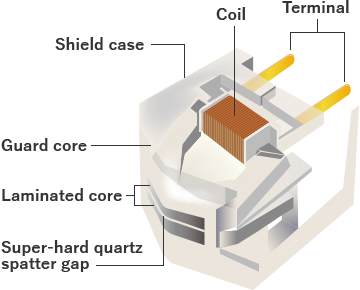

After that, the sales of magnetic head parts (shield case and laminated core) increased significantly for cassette tape recorders that were spreading rapidly.

Shield case and laminated core for cassette tape recorder

Shield case and laminated core for cassette tape recorder

Shield case manufacturing equipment (Transfer press)

Shield case manufacturing equipment (Transfer press)

- Started the production of solenoid coils for the shutter of cameras.

Commentary

We produced solenoid coils used for the shutter opening/closing structure to deliver them to camera manufacturers.

Small-sized shutter magnets for cameras

Small-sized shutter magnets for cameras

- Started the production of components for information equipment (FDD, HDD, MD, CD-ROM, and DISK cleaners)

Commentary

We assembled and manufactured a product that automatically cleans the surface of the disk for information recording such as CD-ROMs.

Disk cleaner for magnetic optical disks

Disk cleaner for magnetic optical disks

September 1971

Changed the company name to Nikkoshi Co., Ltd.

Commentary

The company changed the company name from Japan Industrial Materials Co., Limited, which had been used since its establishment, to Nikkoshi Co., Ltd., which was a nickname used by customers.

1970 -

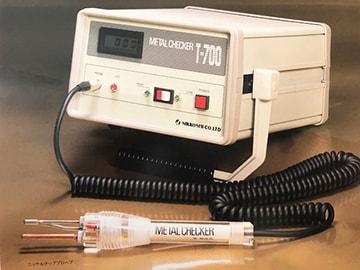

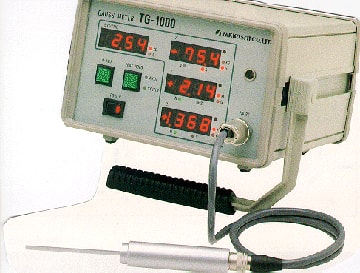

- Started the production of measuring devices (such as metal magnetism stress measuring instrument, material checker, and gauss meter).

Commentary

We designed, manufactured, and sold machines for measuring the magnetic property of various types of metals. The metal magnetism stress measuring instrument (Sigmatron) measures stress in a non-destructive and non-contact manner, applying the magnetostrictive effect generated when a magnetic field is given to an ferromagnetic material.

Metal magnetism stress measuring instrument (Sigmatron)

Metal magnetism stress measuring instrument (Sigmatron)

Material checker

Material checker

Three-dimensional gauss meter

Three-dimensional gauss meter

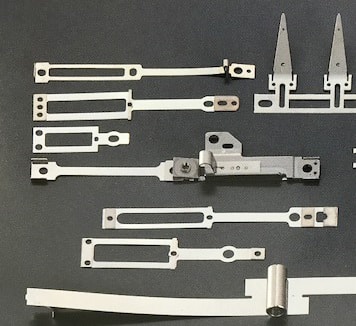

- Started production of HDD parts

Commentary

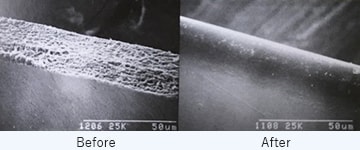

We manufactured and sold steel belts as mechanism components that drive the magnetic heads of hard disk drives (HDDs) at high speed. Since there were countless microscopic cracks on the end face of a steel belt, we performed the PSP process, which was a polishing technology we developed in order to eliminate the cracks. This enabled the extension of the service life, which was highly evaluated as an industry standard.

Steel belts for HDDs

Steel belts for HDDs

PSP processing

PSP processing

Precise Polishing

- Introduced a vacuum heat treatment furnace into the Saitama plant.

Commentary

A heat treatment furnace was introduced for the purpose of heat-treating nuclear power and aircraft parts, and so forth, in a vacuum without causing oxidization. After that, we started the vacuum brazing of industrial equipment parts using nickel-base brazing filler metals.

V01 vacuum heat treatment furnace

V01 vacuum heat treatment furnace

Vacuum Brazing

April 1991

Established the Shirakawa plant in Shirakawa City, Fukushima Prefecture.

Commentary

We established the Shirakawa plant as the second domestic manufacturing base next to the Saitama plant. Initially, the components for VTRs (videotape recorders), which were leading products as video recording media at that time, were produced at this plant. At present, the Shirakawa plant is promoting the development of products centering on magnetic application technology.

The building of the Shirakawa plant

The building of the Shirakawa plant

1990 -

- Started the production of MR sensors (magnetic resistive element).

Commentary

We started the production of MR sensors that can read the magnetic ink on paper currencies to distinguish real ones from fake. After that, the demand for these sensors increased due to the introduction of the euro and the switch to new paper currencies by each country.

MR sensors

MR sensors

MR sensors(magnetic resistive element)

March 1995

Moved the Head Office to Nihonbashi Honcho, Chuo-ku, Tokyo.

- Started the production of electromagnetic proportional valves.

Commentary

We started the production of electromagnetic proportional valves that play a role in proportionally controlling the gas flow. They are installed in mass flow controllers.

Electromagnetic proportional valves

Electromagnetic proportional valves

Solenoids

November 1999

Established Nikkoshi Philippines Corp.

Commentary

Our group’s first foreign manufacturing base was established in Cavite State in the Philippines. Initially, HDD components for which demand was rising as memory media at that time were produced at this plant.

NIKKOSHI PHILIPPINES CORP.

- Started the production of compact solenoids.

Commentary

We started the production of compact solenoids characterized by low profile and high adsorption power using the magnetic circuit designing technology. Initially, the demand for this product as a part for CD-ROM drive for lap top PCs increased. After that, this product has been developed into for various applications such as camera and power-saving switches.

Compact Solenoid

Compact Solenoid

Compact Solenoid

- Started the production of liquid crystal manufacturing device components.

Commentary

By applying the surface treatment technology cultivated in semiconductor manufacturing devices, we started the machining and anodizing treatment of larger liquid crystal manufacturing device components. After that, in order to respond to the demand for large liquid crystal display TVs, which spread rapidly in the 2000s, we promoted the increase in equipment size to address market demands.

Large-sized anodizing treatment facility of Saitama Plant (The maximum treatable size: 3.0 m x 2.7 m)

Large-sized anodizing treatment facility of Saitama Plant (The maximum treatable size: 3.0 m x 2.7 m)

- Established a production base in Cavite, Philippines (Nikkoshi Philippines Corp.).

- Started the overseas production of HDD parts.

May 2000

Established the present Nikkoshi (Hong Kong) Co., Ltd.

2000 -

- Established a trading and sales base in Hong Kong, China (Present Nikkoshi (Hong Kong) Co., Ltd.).

November 2002

Established Zhuhai Nikkoshi Electronics Co., Ltd. (in Zhuhai, Guangdong Province, China).

- Established a production base in Zhuhai, Guangdong, China.

Commentary

Started the manufacture of magnetic-applied electronic components using pressing and heat-treatment.

January 2003

Nikkoshi Philippines Corp. built a new plant and transferred (from Cavite to Batangas, Philippines)

NIKKOSHI PHILIPPINES CORP.

- Established a new production base in Batangas, Philippines, and moved there.

April 2006

Established Nikkoshi (Zhuhai) Electronics Co., Ltd.

- Purchased Kisho Electronics Group to start the handling of winding wires and coils.

Commentary

We started to deliver products directly to HDD manufacturers by purchasing the Kisho Electronics Group, which had superior coil winding and resin molding technologies, to establish an integrated production system for HDD parts on which our part is mounted.

injection-molded coil products

injection-molded coil products

Coil

October 2006

Nikkoshi Philippines Corp. 2nd factory was built.

- Established a new production base (NIKKOSHI (ZHUHAI) ELECTRONICS CO., LTD.) in Zhuhai, Guangdong, China and moved there.

Commentary

In addition to the conventional manufacture of electronic components, we established a new manufacturing base that enabled the anodizing treatment of large-sized liquid crystal panels in South China, in anticipation of the shift of production bases of liquid crystal panels from Japan to China and Taiwan as well as a further increase in the panel size.

ZHUHAI

ZHUHAI

July 2007

Acquisition of Kisho Electronics Co., Ltd., Group.

- Started the production of LED manufacturing device components.

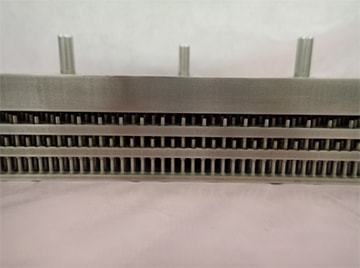

Commentary

We entered into the market for manufacturing devices for LED that are used for lights and TV backlights. Our vacuum brazing technology enabled to form films of multiple gases at one time by forming three-dimensional steric flow passage structures.

The cross-section view of the shower plate for MOCVD devices.

The cross-section view of the shower plate for MOCVD devices.

Vacuum Brazing

June 2011

Zhuhai Nikkoshi Electronics Co., Ltd. was merged with Nikkoshi (Zhuhai) Electronics Co., Ltd., which is a surviving company.

2010 -

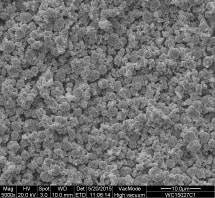

- Started sales of tungsten carbide and cermet spraying materials.

Commentary

We started to directly import tungsten carbide powder, which is the main component of carbide tools, and to sell it to carbide manufacturers to which we had been supplying cobalt powder for carbide tools.

Enlarged photograph of tungsten carbide powder

Enlarged photograph of tungsten carbide powder

Rare Metals

June 2013

Kisho Electronics Co., Ltd., of the wholly owned subsidiary have merged into Nikkoshi Co., Ltd.

April 2014

Moved the head office to Azabudai, Minato-ku, Tokyo.

June 2016

Nikkoshi Electronics Philippines Inc. was merged with Nikkoshi Philippines Corp., which is the surviving company.